WE’RE FIGHTING BACK: THE TRUTH ABOUT “1-DAY” CONCRETE COATING SYSTEMS

An article published in August 2020 by GarageFloorCoating.com sheds light on the dangers of “1-day” coating systems (Polyurea-Polyaspartic One-Day Systems: Do They Work). These popular garage floor coating systems have gained immense popularity. Contractors are fond of them due to their ease and speed of installation. Similarly, customers appreciate them as the contractor completes the job in just one day. However, it is important to remember the age-old saying, caveat emptor (“Let the buyer beware”).

It’s worth pondering, especially in the realm of contractors, how often does “fast” equate to “good”?

What’s a Polyaspartic?

A polyaspartic is a fast-curing coating commonly used in the concrete industry. It offers excellent protection against UV rays, chemicals, and impacts once applied. Additionally, a high-quality polyurea-polyaspartic can even prevent staining from tire marks left by parked cars. These coatings are perfect for as a color coat or providing a durable clear topcoat.

However, there is one drawback to polyurea-polyaspartics: they are not suitable for use as primer coats directly on concrete due to poor bonding in moist conditions. To overcome this limitation, experienced contractors use a moisture-mitigating epoxy as a primer coat and then apply the polyurea-polyaspartic as the clear topcoat. This process does take a bit longer, usually spanning up to 2 days instead of just 1.

Contractors who offer a “1-day” system are aware of this and may try to discredit epoxy products to potential customers. They may also include a warranty exclusion in the contract to protect themselves against any moisture-related issues. It’s important to note that all coating product types, including epoxies, polyurethanes, and polyurea-polyaspartics, have their own strengths and limitations. A reputable contractor should have a diverse range of products in their arsenal to ensure the best results for each project.

Why Don’t “1-Day” Systems Warrant Moisture-Related Issues?

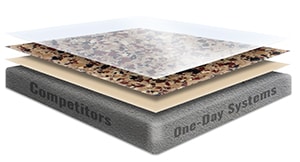

Using a thin coat of polyurea-polyaspartic for direct-to-concrete application in “1-day” coating systems is not recommended as they delaminate over time in medium to high moisture vapor transmission. Contractors use this system as it requires less product and labor, making it profitable for them. However, the warranty excludes “high-moisture conditions” and often, tire staining. Considering these limitations, is investing in a concrete coating even worth it?

Us Versus Them

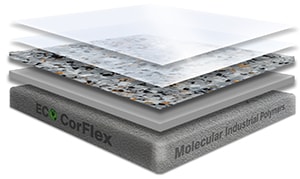

Our thick garage floor coatings are guaranteed against moisture-related conditions and tire staining, as well as most automotive fluids. We take pride in using industrial-grade polyurea-polyaspartic coatings in every garage, applying two clear top coats for maximum protection. It’s important to note that we never use polyureas as direct-to-concrete primers…it is this that ensures the longevity of our coatings.

What also sets us apart from the competition is our use of proprietary mica stone blends in our full-chip, mica stone concrete coatings. Unlike others who use thermoplastic, our floors are thicker, stronger, and more visually appealing. Our Bagari SE and Vintage Mica series, which incorporate an ultra-thick 100%-solids moisture-mitigating primer coat, a full-chip mica-infused broadcast, and two 100%-solids polyurea-polyaspartic top coats with anti-skid properties, result in garage floor coatings over 35 mils thick. This is why we confidently offer a warranty against moisture-related issues and “hot tire transfer,” which are the leading causes of coating system failures.

If you’re looking for stunning, industrial-grade, full-chip garage floor coatings with a real lifetime warranty, don’t hesitate to reach out to us. Call us or click here for your free estimate. We’re here to provide you with the best solution for your garage flooring needs.